SAFETY AS A SERVICE

NDTDS provides advanced contact and contactless NDT solutions via robotic aerial systems – improving safety, reducing inspection costs, and maximizing asset uptime. Our drone-deployed inspection services let you inspect at height, in operation, and in hazardous areas without risking personnel or interrupting production.

Core Offerings

The Future of Surface Integrity Monitoring Is Airborne

Our team provides precision contact NDT at elevation using a drone with full orientation control. This system approaches structures from any angle, maintaining stable surface contact with rotating thrusters—even on vertical or inverted surfaces.

It eliminates the need for scaffolding or rope access while enabling in-service inspections on hot assets like flare stacks or process vessels.

UT & High-Temp UT

In-Service, Elevated Inspections

Our team provides UT on structural steel at height—even on surfaces reaching 260 °C. One drone mission replaces multi-day shutdowns with hour-long surveys—saving time, risk, and money.Pulse Eddy Current

Detecting Corrosion Under Insulation

Without removing cladding or insulation, PEC detects metal loss beneath protective layers. Through 100mm insulation, we can identify early-stage corrosion, enabling fast, safe evaluations of CUI without teardown.EMAT

Contactless Thickness Scans

On aging infrastructure, EMAT generates ultrasound within the material—no couplant, grinding, or prep required. It detects thinning, cracking, and delamination under paint, rust, or scale, preserving surface integrity.DFT

Coating Thickness Verification

DFT measures dry film thickness on tanks, stacks, and bridges to confirm compliance with coating standards. Drone deployment verifies coverage and reveals potential undercoated areas—without ladders or lifts.

DOC in Action – Mapping Subsurface Pipelines

In partnership with Skipper NDT, we offer drone-mounted, magnetometer based, subsurface intelligence across large pipeline corridors. This technology delivers precision data on pipeline location, soil cover, and signs of mechanical strain—all without boots on the ground or breaking soil.

By capturing magnetic field anomalies from above, we can provide safe, fast, non-invasive assessments that complement or replace manual surveys and ILI-only programs.

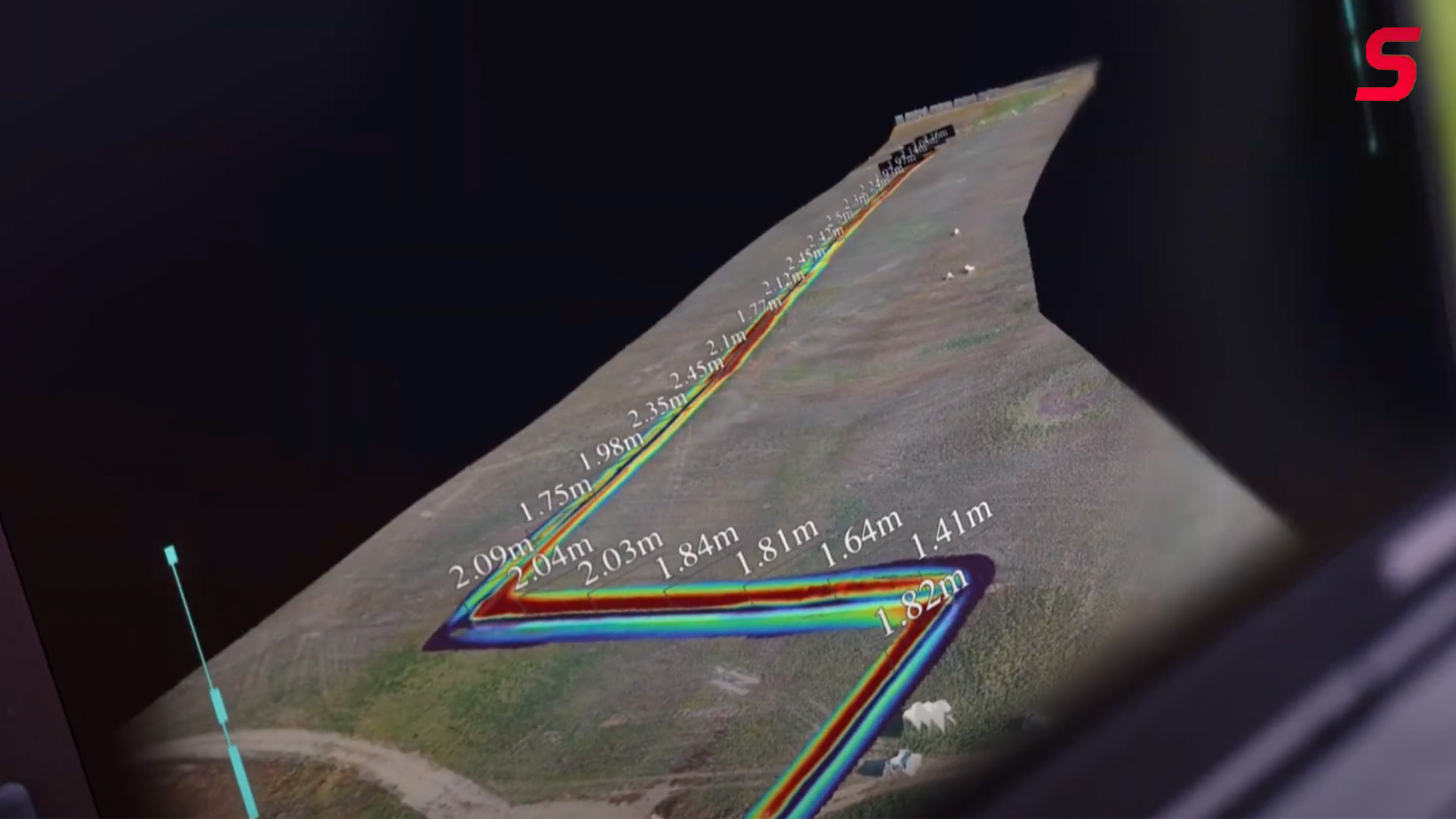

Detecting Depth-of-Cover

Magnetometer Based Scan

Wielding high-sensitivity drone mounted magnetometers, we can to trace the exact path and depth of steel pipelines. Gain centimeter-accurate profile of soil cover thinning and erosion—supporting DOT compliance and reducing strike risk.

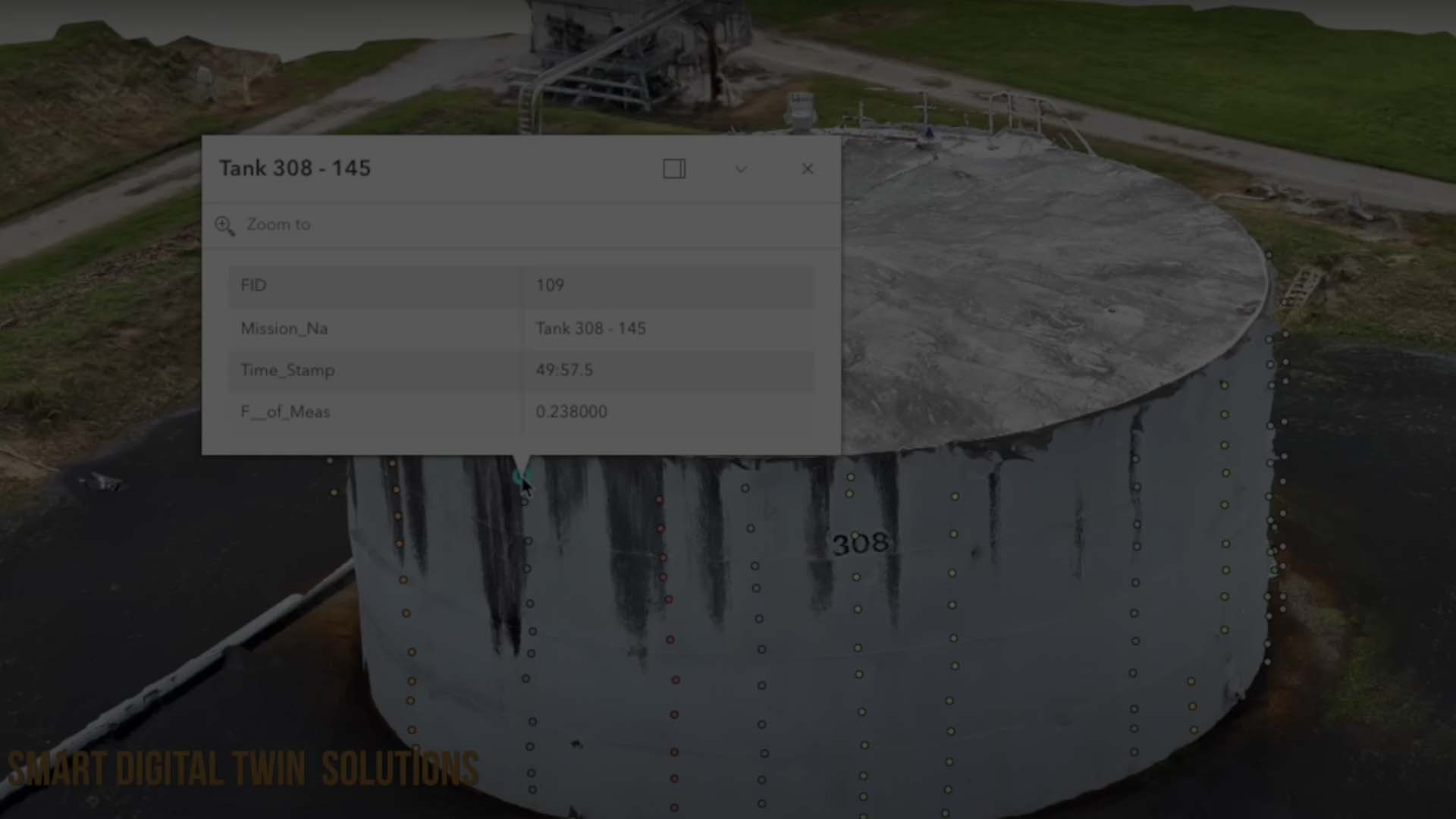

Correlating ILI Data

ILI Locations Mapped

Integrating drone-collected data with ILI findings matches internal defects to their exact location in the field. This turns raw anomaly reports into dig-ready, geo-referenced intelligence, reducing unnecessary digs and improves response planning.

Bend Strain Analysis

Rapid Data When It Matters Most

Geohazards like ground movement and landslides often go undetected until the moment of failure. Mag data flags bending strain caused by shifting terrain or subsidence, before the pipe reaches critical deformation thresholds.

Asset Modeling

Pipeline Intelligence Visualized

By combining depth, curvature, and field strain data with UAV based terrain models over land (and water!), we provide easy to understand reports and models of your active pipelines, even in complex and challenging environments.

Thermal Oversight for Critical Infrastructure

NDTDS deploys high-resolution thermal drones to perform non-contact, in-service inspections of industrial assets operating under thermal stress. Our systems deliver accurate, repeatable IR data enabling detection of heat loss, combustion irregularities, structural deformations, and insulation failures across flare systems, storage tanks, piping networks, and mechanical infrastructure.

Each mission is engineered to reduce risk, eliminate access challenges, and provide actionable thermal intelligence without interrupting operations.

Flare Stack & Pilot Flame Inspection

Combustion insight without shutdown

NDTDS deploys radiometric thermal drones to inspect flare tips and pilot systems, detecting flame asymmetry, low-temp burn zones, and outages, eliminating the need for scaffolding while maintaining process safety and emissions compliance.

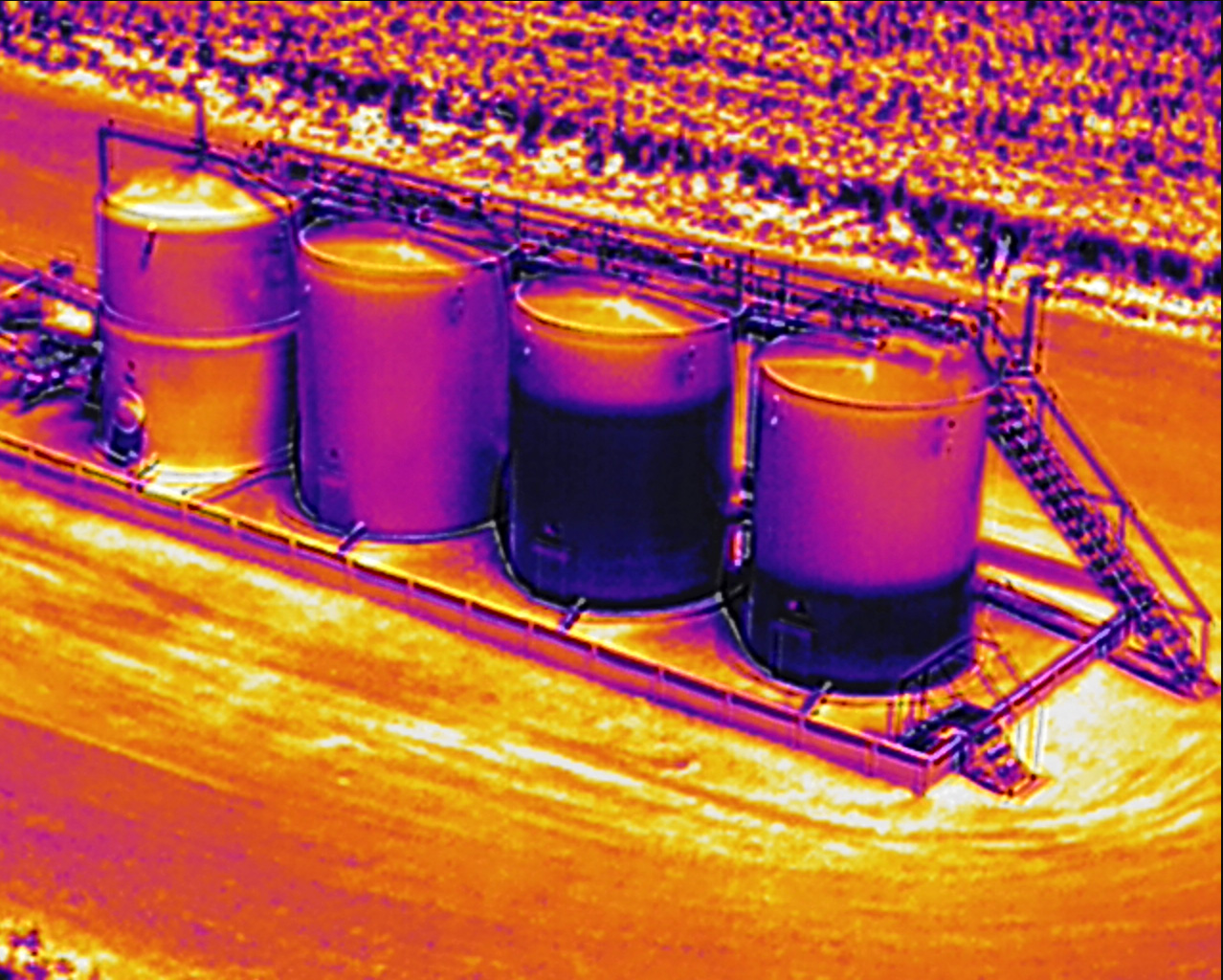

Tank Deformation & Product Level Assessment

Structural heat mapping, non-invasive

NDTDS uses thermal drones to detect wall temp gradients in storage tanks, identifying internal deformation, bulging, or partial fill levels—without contact, confined space entry, or shutdowns—while reducing reliance on scaffolding.

High-Temperature Asset Fault Detection

Detect faults in thermal profiles

Thermal drones capture delta-T profiles across boilers, furnaces, and flares to identify insulation loss, refractory damage, and more, allowing operators to address faults in real-time without interrupting service or exposing teams to high-temps.

Heat Loss & Energy Efficiency Audits

Expose insulation loss, drive savings

NDTDS conducts aerial thermal audits of insulated systems to detect heat loss, conduction bridging, and air leakage, providing georeferenced thermal maps for targeted remediation while supporting compliance and reducing energy costs.